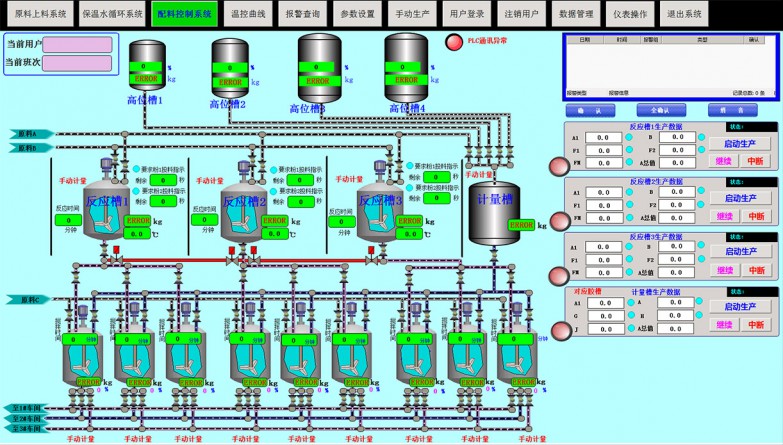

Hctech Weighing Equipment Co., Ltd. design and manufacture of automatic weighing dosing control system can quickly complete the liquid, quasi-dynamic measurement of powder materials accurately, which can be a variety of liquids and powders real-time quality testing, having all aspects of production in real-time monitoring, data collection, statistics, reports, print and other functions. The complete system can be manually or automatically scheduled reactor feed accurately, frequency mixing, the finished product tank, finished filling barrels, tankers, etc. Accurate measurement and automatic control is widely used dipped tire cord, pharmaceutical, chemical ingredients in edible oil, food processing, dairy, fruit juice, mixing stations and other industries feeding, filling and piped.

Automatic Weighing and Batching System

dipped Weighing Control System Design features:

1, continuous measurement of the dynamic manner in solid, liquid quantitative measurement of powder material, can control the speed of investment, both to improve accuracy, and ensure productivity.

2, centralized control console, configuration software, can respond quickly to changes in customer needs, friendly interface, the operator can monitor the working status of the production line in the control room, to improve the efficiency and speed of exception handling;

3, weighing instruments centralized installation, making monitoring software and PLC communicate with more convenient, safe and reliable;

4, production management software is powerful, can complete a variety of production formula management, process control, exception alarm and production data collection, storage, reporting, analysis and printing;

5, easy to upgrade expansion, you need to expand the existing system, the new system will only mount the sensor leads, the valve control line into the control room, and to increase the corresponding function modules in the software interface, simple and quick.

6, with the tank pressure, liquid level detection, can be installed in the raw material tank level gauges, pressure sensors, centralized control center level, pressure and other real-time monitoring, to avoid accidents.